Product Description

Product Description

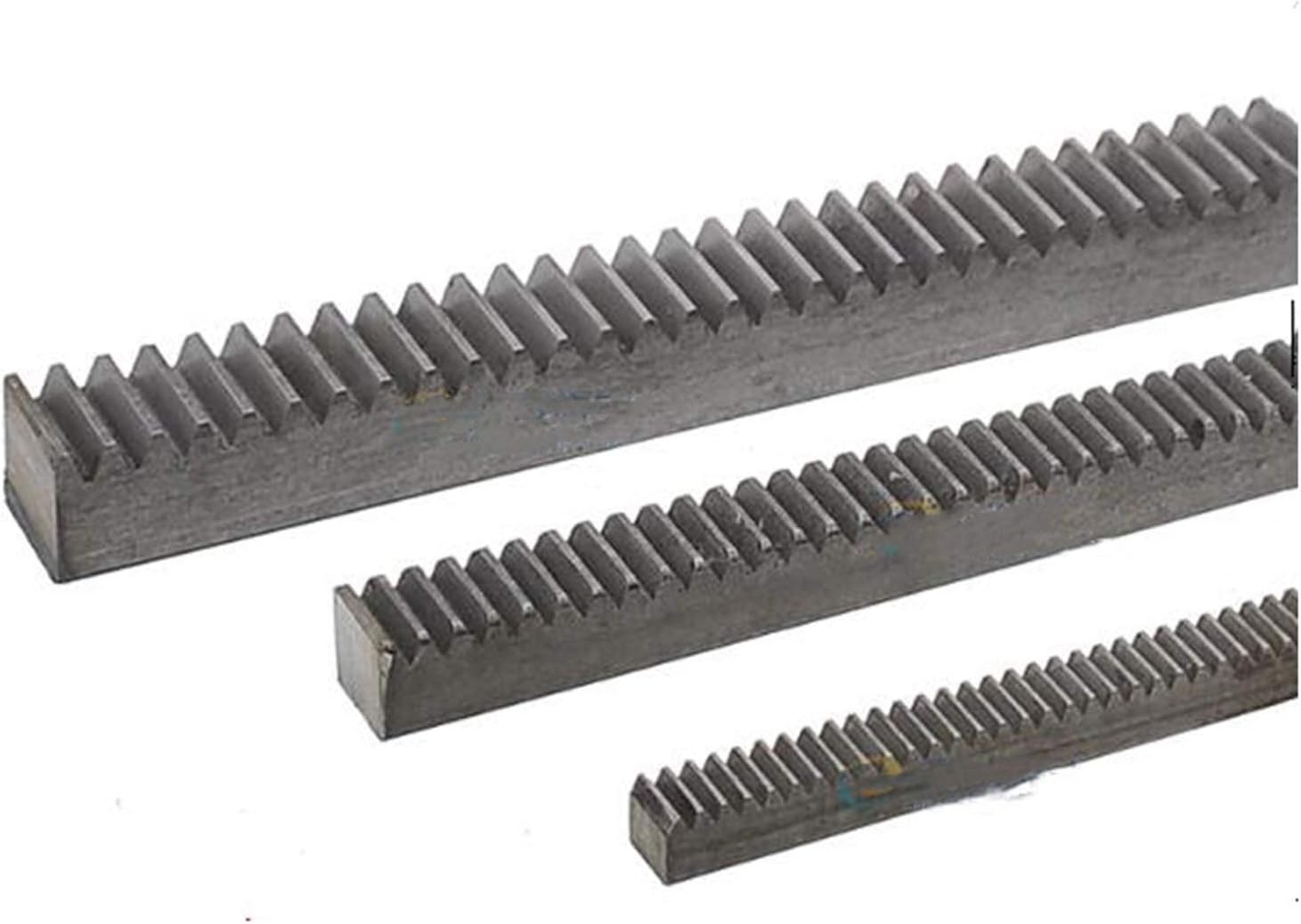

Features

1. Available in sizes in Module1.5/2/3/4/5/6/7/8/9/10

2. Repeatability of up to ± 0.01mm

3. Powerful rack and pinion drives for reliable movements.

4. Extremely compact frame with high inherent stiffness

5. It is designed for high-temperature resistance, long service life.

6. Rigidness improved, Smaller size, Easy to maintain, Improve accuracy, Easy assemble, etc.

Operation

1. The operation conditions need to be within the rated values as shown in the technical information.

2. Avoid dust, debris, and any foreign objects from entering the rack and pinion return system.

3. The operational temperature should be under 80 ºC. In high-temperature environments above 80ºC.

4. If the product can be used in a special environment, such as vacuum, vibration,

clean room, corrosive chemicals, organic solvents, extremely high or low temperatures, humidity, liquid splashes,

oil drops or mist, high salt, heavy load, vertical or cantilever installations. Please Confirm first with TOCO.

5. For vertical installations, when loaded, there is a possibility that the slider may fall. We recommend adding

proper braking and ensure functionality before the operation.

Maintenance

1. Lubricate the product before the initial use. Note the type of grease used and avoid mixing different types together.

2. For normal operating conditions, it is recommended to check the operation every 100km, clean and supply grease CHINAMFG the rack and pinion.

| Brand | TOCO |

| Model | Rack and pinion |

| Size customize | Module1.5/2/3/4/5/6/7/8/9/10 |

| HS-CODE | 8483900090 |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, Western Union |

| Production lead time | 15 business days for sample, 35 days for the bulk |

| Keyword | Rack and pinion |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

Catalogs

Package & Shipping

1.Package: Carton or wooden case.

2.Delivery time: 15 days after receiving payment.

3.Shipping: by express (DHL, TNT, FedEx, etc.) or by sea.

TOCO Exhibition

ZheJiang brand registered trademark, High-Tech Enterprise, letter patents, and ISO.

FAQ :

1. Service :

a. Help customers to choose the correct model, with CAD & PDF drawing for your reference.

b. Professional sales team, make your purchase smooth.

2.payment :

Sample order: We require 100% T/T in advance. sample express need request pay by clients

Bulk order: 30% T/T in advance, balance by T/T against copy of B/L.T/T, Paypal, Western Union is

acceptable.

3.Delivery :

sample: 5-10 business days after payment confirmed.

Bulk order:10-20 workdays after deposit received.

4. Guarantee Time

CHINAMFG provides a one-year quality guarantee for the products from your purchase date, except for

the artificial damage.

5.After sale-Service

During the warranty period, any quality problem of the CHINAMFG product, once confirmed, we will

send a new 1 to replace. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, CNC Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Straight/Helical |

| Material: | Stainless Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with spur gear racks?

When working with spur gear racks, it is important to keep several safety considerations in mind to ensure the well-being of personnel and the proper functioning of the equipment. Here are some key safety considerations to be aware of:

- Entanglement and Pinch Points: Spur gear racks have rotating parts and moving components. It is crucial to be cautious of entanglement and pinch points during installation, operation, and maintenance. Keep hands, clothing, and other loose items away from the gear rack and associated machinery while it is in motion. Use appropriate guards or protective covers to prevent accidental contact with the gears and rotating parts.

- Lubrication and Maintenance: Proper lubrication is essential for the smooth operation of spur gear racks. Follow the manufacturer’s guidelines regarding the type and amount of lubricant to be used. Regularly inspect and maintain the gear rack system to ensure that it remains in good working condition. Replace worn-out or damaged components promptly to prevent potential hazards and maintain optimal performance.

- Load Capacity and Overloading: Spur gear racks have specific load capacities that should not be exceeded. It is important to understand the load limits of the gear rack and ensure that the equipment or machinery it is integrated with operates within those limits. Overloading can lead to premature wear, tooth failure, and potential accidents. Refer to the manufacturer’s specifications and guidelines to determine the appropriate load capacity for the gear rack.

- Proper Installation: Ensure that the spur gear rack is correctly installed according to the manufacturer’s instructions. Improper installation can result in misalignment, which may cause excessive wear, noise, and reduced performance. Follow proper alignment procedures and use appropriate tools and techniques to secure the gear rack in place. If unsure, consult with a qualified professional or the manufacturer for guidance.

- Noise and Vibration: Spur gear racks can generate noise and vibration during operation. Excessive noise and vibration may indicate issues such as misalignment, inadequate lubrication, or worn-out components. Regularly monitor the gear rack system for unusual noise or excessive vibration and promptly investigate and address any potential problems to avoid safety hazards and equipment failure.

- Training and Awareness: Ensure that personnel working with spur gear racks receive appropriate training and instructions on safe operating procedures. Familiarize them with the potential hazards associated with gear rack systems and educate them on how to safely perform tasks such as maintenance, inspection, and troubleshooting. Encourage a safety-conscious culture and promote awareness of potential risks.

- Emergency Stop and Shutdown: Make sure that the equipment or machinery integrated with the spur gear rack has emergency stop mechanisms in place. Clearly label and identify emergency stop buttons or switches and ensure that personnel know their locations and how to use them. Regularly test the emergency stop function to verify its effectiveness. In case of any abnormalities or emergencies, immediately initiate the shutdown procedure and follow appropriate safety protocols.

- Protective Equipment: When working with spur gear racks, it is advisable to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and protective clothing. PPE can provide an additional layer of protection against potential hazards, such as flying debris, sharp edges, or accidental contact with moving parts.

These safety considerations are essential for maintaining a safe working environment when dealing with spur gear racks. By following proper safety practices, personnel can minimize the risk of accidents, ensure the longevity of the equipment, and promote a culture of safety within the workplace.

Can spur gear racks be used in manufacturing and industrial machinery?

Yes, spur gear racks are commonly used in manufacturing and industrial machinery due to their versatility, robustness, and ability to transmit power and motion efficiently. They find numerous applications in these sectors, contributing to the smooth operation and precise control of various processes. Here’s a detailed explanation of how spur gear racks are utilized in manufacturing and industrial machinery:

- Conveyor Systems: Spur gear racks are employed in conveyor systems to facilitate the movement of materials or products along a linear path. The gear rack, driven by a motor or a chain drive system, engages with a pinion gear to provide continuous and controlled linear motion. Gear racks ensure precise and synchronized movement of the conveyor belts, allowing for efficient material handling and automated production processes.

- Motion Control Systems: Spur gear racks play a crucial role in motion control systems found in manufacturing and industrial machinery. They are used to convert rotary motion into linear motion or vice versa, enabling precise positioning, actuation, and synchronization of components. Gear racks, along with motors, actuators, or hydraulic systems, provide accurate and repeatable linear movement, allowing for tasks such as part feeding, assembly, or robotic motion control.

- Machine Tools: Spur gear racks are utilized in various machine tools, such as milling machines, lathes, or grinding machines. They enable the movement of tool heads or workpieces along linear axes, facilitating cutting, shaping, or machining operations. Gear racks provide the necessary rigidity, precision, and load-carrying capacity required in these high-precision machining processes.

- Industrial Robots: Spur gear racks are integral components in the drive systems of industrial robots. They enable precise and controlled linear movement of robot arms and end effectors. Gear racks, along with servo motors or actuators, allow industrial robots to perform tasks such as pick-and-place operations, assembly, welding, or material handling with high accuracy and repeatability.

- Packaging Machinery: In packaging machinery, spur gear racks are used for the linear movement and control of packaging components, such as conveyors, guides, or sliding mechanisms. They ensure synchronized and precise motion, enabling efficient packaging processes, filling operations, or product sorting in industries like food and beverage, pharmaceuticals, or logistics.

- Printing and Paper Handling Systems: Spur gear racks find applications in printing presses and paper handling systems, where precise and synchronized movement is essential. They enable the linear positioning and control of printing heads, paper feed mechanisms, or cutting systems. Gear racks ensure accurate registration, smooth paper transport, and reliable operation in printing and paper processing equipment.

Overall, spur gear racks are widely utilized in manufacturing and industrial machinery to provide efficient power transmission, precise linear motion, and control. Their robustness, high load capacity, and ability to handle demanding operating conditions make them ideal for a range of applications in these sectors, contributing to increased productivity, accuracy, and automation in various manufacturing processes.

Can you explain the purpose and applications of spur gear racks in machinery?

Spur gear racks serve various purposes and find widespread applications in machinery across different industries. They are commonly used for the conversion of rotational motion into linear motion or vice versa. Here are some key purposes and applications of spur gear racks:

Motion Conversion: One of the primary purposes of spur gear racks is to convert rotational motion into linear motion. By meshing with a pinion gear, the teeth on the rack translate the rotational movement of the pinion into a linear movement along the length of the rack. This linear motion can be utilized to drive various mechanisms and components in machinery.

Positioning and Precision: Spur gear racks are often employed for precise positioning tasks in machinery. The linear motion provided by the rack allows for accurate movement and positioning of components, tools, or workpieces. This is particularly useful in applications such as CNC machines, where precise positioning is critical for machining operations.

Power Transmission: Spur gear racks are used to transmit power between different components in machinery. By incorporating a pinion gear that meshes with the rack, rotational motion can be transferred from one part of the machinery to another. This enables the transmission of power to drive various mechanisms, such as conveyors, lifts, or other linear motion systems.

Steering Systems: Spur gear racks play a crucial role in rack and pinion steering systems, commonly used in automobiles and other vehicles. The rotational motion of the steering wheel is converted into linear motion through the interaction between the pinion gear and the rack. This allows for precise control of the vehicle’s steering, enabling the driver to navigate and maneuver the vehicle.

Linear Actuators: Spur gear racks are utilized in linear actuator systems to generate linear motion for pushing, pulling, or positioning loads. The rack and pinion configuration provides a simple and efficient method for converting rotational motion into linear motion. Linear actuators employing spur gear racks are used in various applications, including robotics, industrial automation, and machinery positioning systems.

Machine Tools: In machine tools such as milling machines, lathes, and drilling machines, spur gear racks are employed for precise movement and positioning of cutting tools or workpieces. The linear motion provided by the rack enables controlled and accurate machining operations, contributing to the overall performance and quality of the machined parts.

Automation and Robotics: Spur gear racks are widely used in automation and robotics systems. They facilitate linear motion for the movement of robotic arms, conveyors, and other automated mechanisms. The precise and controlled motion offered by spur gear racks is instrumental in achieving accurate and repeatable operations in automated processes.

Industrial Machinery: Spur gear racks find applications in various industrial machinery, including packaging machines, printing presses, textile machinery, material handling systems, and more. They contribute to the efficient and reliable operation of these machines by providing linear motion, power transmission, and precise positioning capabilities.

Overall, spur gear racks play a vital role in machinery, enabling linear motion, precise positioning, power transmission, and automation. Their versatility and reliability make them a fundamental component in numerous applications across diverse industries.

editor by Dream 2024-05-06