Description

Hardened Ground Racks

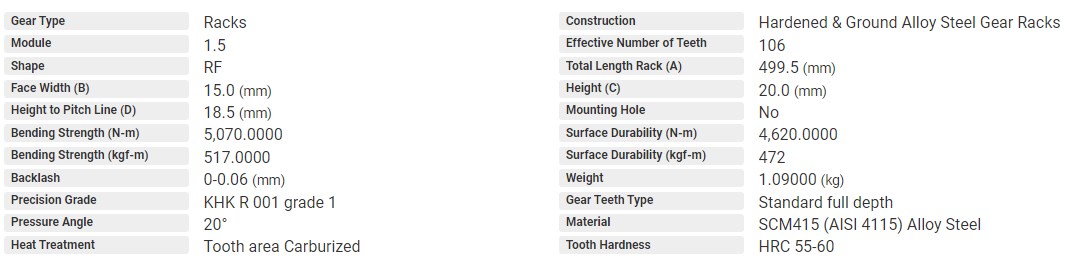

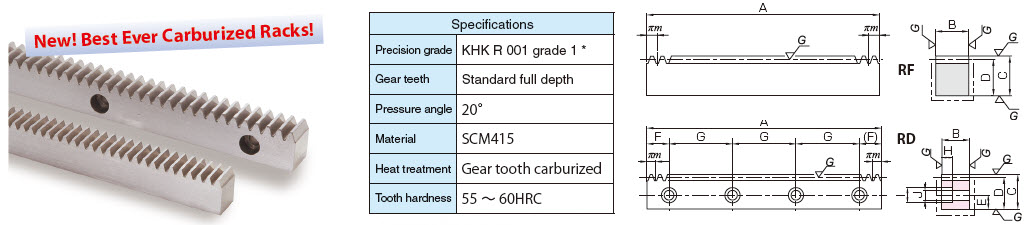

Hardened ground racks are an essential component in various machinery and equipment, offering unparalleled precision and enhancing overall performance. With their durable construction and exceptional quality, these racks are widely used in industries such as manufacturing, automation, and robotics. In this article, we will delve into the features, usage methods, and maintenance of hardened ground racks, highlighting their crucial role in driving efficiency and accuracy.

Features of Hardened Ground Racks

- Hardened Surface: Hardened ground racks are crafted from high-quality materials with specially treated surfaces, ensuring exceptional hardness and wear resistance. This feature allows them to withstand heavy loads and repetitive motion without compromising their structural integrity.

- Precision Machining: These racks undergo precise machining processes to achieve high dimensional accuracy and consistent tooth profiles. The precise tooth geometry guarantees smooth and efficient operation, enabling seamless engagement with accompanying gears.

- Ground Finish: The racks’ surfaces undergo a specialized grinding process, resulting in a smooth and flawless finish. This ground finish minimizes friction and noise during operation while maintaining optimum meshing with compatible gears.

Usage Method

- Compatibility Assessment: Before integrating hardened ground racks into your machinery, it is vital to ensure compatibility with the existing gear system. Evaluate the required module, pitch, and tooth profile to select the appropriate rack for your application.

- Proper Mounting: Securely mount the hardened ground rack in a designated position, aligning it accurately with the accompanying gear. Pay close attention to the alignment to prevent any misalignment or unnecessary strain on the system.

- Lubrication: To ensure smooth and efficient operation, apply a suitable lubricant to the tooth surfaces. Regular lubrication not only reduces friction but also prolongs the lifespan of the rack, enhancing its overall performance.