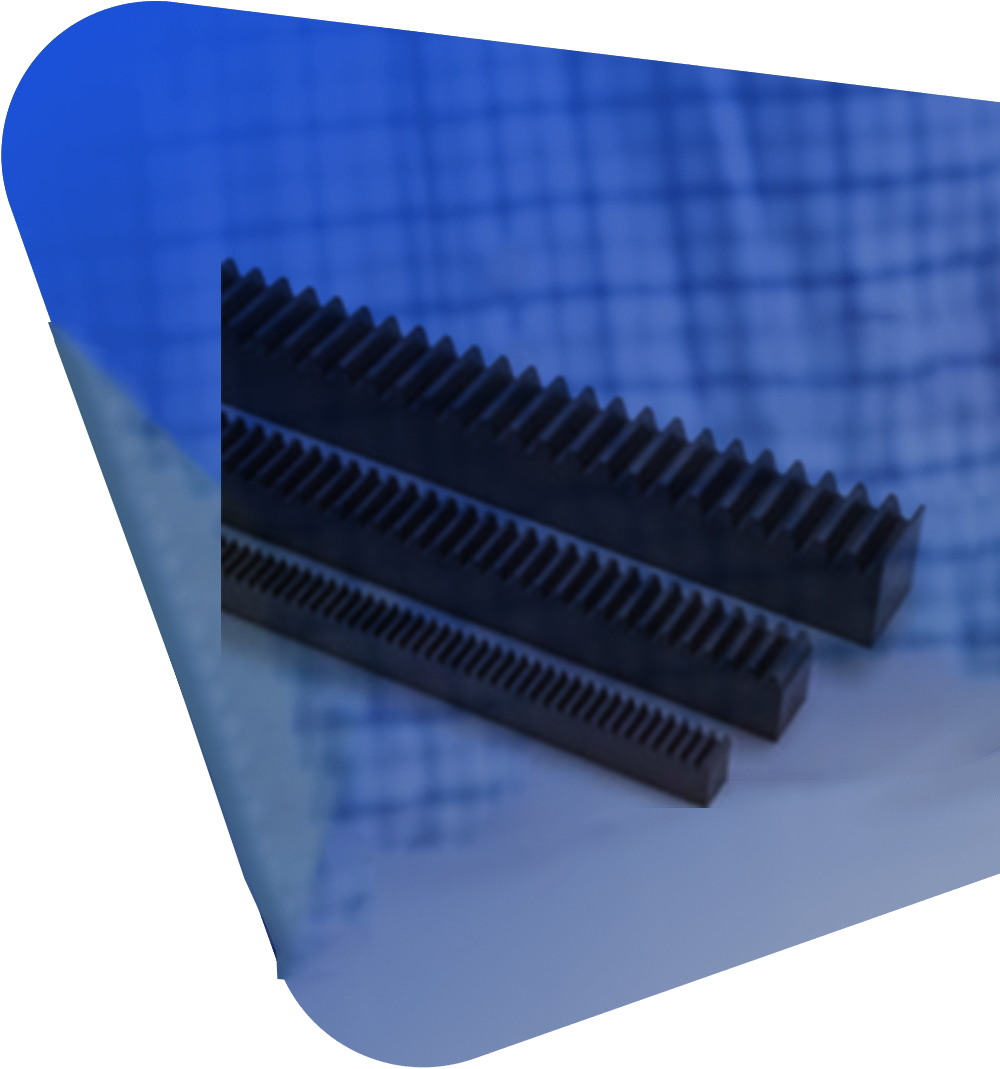

China Gear Rack Manufacturer

A rack and pinion is used to convert rotary motion into linear motion. A rack is a tiny cylindrical gear that meshes with a rack and has straight teeth cut into one face of the square or circular portion of the rod. In general, “rack and pinion” means a rack and pinion.

Construction of Gear Racks

Gear racks are typically constructed using a combination of manufacturing processes and materials to ensure their durability and precision.The exact construction process may vary depending on the manufacturer and specific application requirements. However, the key principles of material selection, tooth cutting, heat treatment, finishing, and quality control are common steps involved in the construction of gear racks. Here is a general overview of the construction of gear racks:

Material Selection

Gear racks are commonly made from high-quality materials such as steel or alloy steel. These materials offer excellent strength, wear resistance, and durability, making them suitable for withstanding heavy loads and prolonged use.

Cutting Teeth

The gear rack starts as a long, straight bar with parallel sides. The next step involves cutting the teeth along one side of the bar. Various methods can be used for this, including gear hobbing, gear shaping, or broaching. These processes involve using specialized cutting tools or machines to accurately carve the teeth profile into the rack. The tooth profile may be straight, helical, or have a custom design depending on the specific application requirements.

Heat Treatment

After the teeth cutting process, the gear rack may undergo heat treatment to enhance its mechanical properties. Heat treatment involves subjecting the gear rack to controlled heating and cooling processes to modify its hardness, strength, and toughness. This step helps improve the gear rack’s resistance to wear, fatigue, and deformation under heavy loads.

Finishing Processes

Once the teeth cutting and heat treatment are complete, the gear rack undergoes finishing processes to refine its surface and ensure dimensional accuracy. These processes may include grinding, milling, or lapping to achieve a smooth surface finish and precise tooth geometry. The finishing processes help ensure smooth and precise meshing with the pinion gear.

Inspection and Quality Control

Before being released for use, the gear racks undergo rigorous inspection and quality control procedures. This typically involves dimensional measurements, tooth profile analysis, and other tests to verify the gear rack’s adherence to specified tolerances and quality standards. Any defective or non-conforming gear racks are rejected to maintain the highest level of quality.

Gear Rack for Sale

As a gear rack manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Gear Rack and Pinion

A gear rack and pinion system is a mechanical arrangement commonly used to convert rotational motion into linear motion. It consists of two main components: a gear rack and a pinion gear. The gear rack is a long, straight toothed bar with parallel teeth running along its length, while the pinion gear is a small, round gear with teeth that mesh with the gear rack. When the pinion gear rotates, it engages with the gear rack, causing it to move linearly. This arrangement is often used in various applications, including automotive steering systems, industrial machinery, and robotics, where precise and efficient linear motion is required. The gear rack and pinion system offer advantages such as simplicity, compactness, high efficiency, and the ability to transmit large forces.Pellentesque fermentum faucibus venenatis. Proin porttitor sem eget varius mollis. Sed vel convallis dui. Proin hendrerit neque suscipit neque iaculis, non condimentum risus fringilla. Cras blandit urna sit amet mi lobortis, id volutpat mi semper. Sed ullamcorper accumsan tellus, in mattis mauris consectetur.

Why Choose Us

our gear rack products deliver precision, durability, efficiency, and customization options, making them an excellent choice for customers seeking reliable and high-performance gear rack systems.

Precision and Accuracy

Our gear rack products are designed and manufactured with utmost precision, ensuring accurate and repeatable linear motion. The teeth on our gear racks are precisely cut to mesh seamlessly with the pinion gear, resulting in smooth and precise movement. This level of accuracy is crucial in applications where precision positioning is required, such as CNC machines or robotic systems.

Efficiency and Energy Savings

Our gear rack systems are designed to maximize efficiency, ensuring optimal power transmission from the pinion gear to the gear rack. The smooth meshing of teeth and minimal friction result in minimal energy loss, making our gear racks energy-efficient. By reducing energy consumption, our gear rack products contribute to cost savings and sustainability efforts.

Durability and Reliability

Our gear rack products are built to withstand demanding conditions and heavy loads. We use high-quality materials and employ advanced manufacturing techniques to ensure excellent durability and reliability. Whether used in industrial machinery or automotive applications, our gear racks offer long-lasting performance, minimizing downtime and maintenance costs.

Customization and Versatility

We understand that different applications have unique requirements. Therefore, we offer customization options for our gear rack products. Customers can choose from a range of sizes, materials, tooth profiles, and mounting options to suit their specific needs. Whether it’s a compact size for limited space or a specialized tooth profile for high-speed applications, we provide tailored solutions to meet diverse customer requirements.

Gear Rack Application

Automotive Steering Systems

Gear racks play a crucial role in automotive steering systems, especially in rack and pinion steering setups. The gear rack is connected to the steering wheel through the pinion gear, enabling the conversion of rotational motion into linear motion. This mechanism allows for responsive and precise steering control, ensuring safe and reliable vehicle maneuverability.

CNC Machines

Computer Numerical Control (CNC) machines, such as milling machines and laser cutters, often employ gear racks to achieve precise linear movement. The gear rack, driven by a motor through a pinion gear, controls the X, Y, and Z-axis movement of the machine’s cutting or machining tool. Gear racks provide the accuracy and stability required for intricate and high-precision machining operations.

Industrial Automation and Robotics

Gear racks are widely used in industrial automation and robotics applications. They are employed in linear actuators to provide controlled linear motion for various tasks, including material handling, assembly, and pick-and-place operations. Gear racks enable robots and automated systems to move with precision, speed, and efficiency, facilitating increased productivity in manufacturing environments.

Frequently Asked Questions

What Material Is Used to Manufacture Your Gear Racks?

Our gear racks are typically made from high-quality steel or stainless steel, ensuring durability and strength.

What Are the Available Module and Pitch Options for Your Gear Racks?

We offer a range of module and pitch options, including commonly used ones such as module 1, module 1.5, module 2, and corresponding pitches such as 20, 30, and 40.

Can You Provide Custom Gear Rack Sizes and Specifications?

Yes, we offer customization services and can manufacture gear racks according to your specific requirements, including different lengths, tooth profiles, or special features.

What Types of Tooth Profiles Are Available for Your Gear Racks?

We offer various tooth profiles such as straight tooth, helical tooth, and round tooth, depending on your application and specific needs.

What Surface Treatments or Coatings Do You Offer for Your Gear Racks?

Our gear racks can be supplied with different surface treatments and coatings, such as black oxide, zinc plating, or nickel plating, to enhance corrosion resistance and improve performance.

Can You Provide Technical Drawings or Specifications for Your Gear Racks?

Yes, we can provide detailed technical drawings and specifications for our gear racks upon request, including dimensions, tolerances, and tooth profiles.

What Is the Load Capacity and Precision Rating of Your Gear Racks?

Our gear racks are designed to handle varying load capacities depending on their size and material. We can provide load capacity information and precision ratings based on your specific requirements.

Do You Offer Any Additional Accessories or Complementary Products for Gear Rack Installation?

Yes, we provide accessories such as mounting brackets, gear rack clamps, and lubricants that can facilitate the installation and maintenance of our gear racks.

What Is the Lead Time for Manufacturing and Delivering Gear Racks?

The lead time can vary depending on the order quantity and customization requirements. We can provide you with an estimated lead time once we have all the necessary details of your order.

What Is Your Warranty or Guarantee Policy for Gear Racks?

We stand behind the quality of our gear racks and offer a warranty against manufacturing defects. The specific warranty period and conditions can be discussed during the purchasing process.

Manufacture Custom Spur Gear Racks to Your Exact Specifications

At EPT, we can assist with design, modification, prototyping, and complete production of custom drive components and gears for any application. If your project specifications call for custom mechanical components, our engineering team can produce components that match your drawings and meet your performance needs.